In some factories, many employees are expected to have heard about problems with hydraulic joints. Stainless steel hydraulic joint is a particularly important part of the machine equipment, it is mainly composed of motor, hydraulic pump, hydraulic valve and so on. However, most people do not know much about this joint. Here we will introduce the related problems of stainless steel hydraulic joint.

First, what are the application categories of stainless steel hydraulic joints

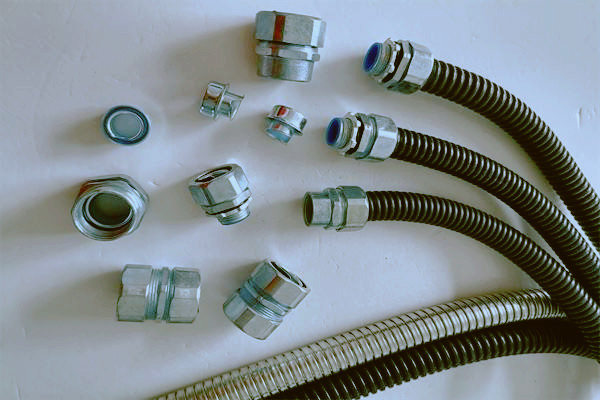

Since the 1930s, stainless steel hydraulic joints have been widely used in some capitalist countries. With the passage of time, they have not been eliminated. Although its joint body and the structural form of the joint nut has not changed much, but in order to comply with the development of the whole era, it has developed into the fourth generation now. Because it is a component of hydraulic tubing connections, it plays an important role in machines and other liquid pipelines.

Second, what are its effects and benefits

Speaking of hydraulic joint, in fact, most people do not know much about it, but feel that it is a part and relatively widely used. However, it can effectively reduce the production process and production processing links in the process of use, and finally can achieve the purpose of cost control.

Through the above introduction, it is estimated that we have a simple understanding of this joint. In fact, although it is made of stainless steel metal products, but it is used to do the connecting head, not only has corrosion resistance, wear resistance and high toughness, but also the gap generated by it is relatively small. If separated from some base metals, it is relatively firm, and the connection is particularly good. But we also need to be careful when using it to avoid causing some unnecessary harm.